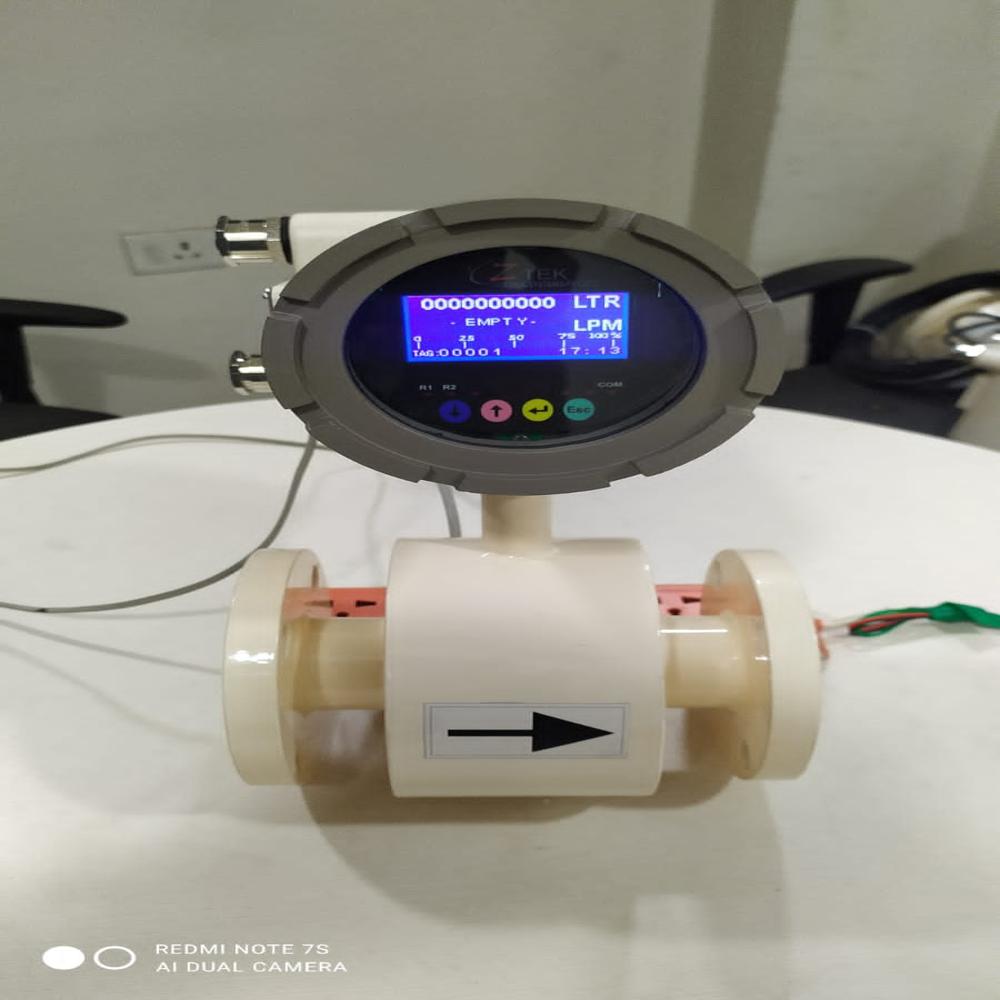

विदà¥à¤¯à¥à¤¤ à¤à¥à¤®à¥à¤¬à¤à¥à¤¯ à¤à¤² पà¥à¤°à¤µà¤¾à¤¹ मà¥à¤à¤°

Price 19500.0 आईएनआर/ टुकड़ा

विदà¥à¤¯à¥à¤¤ à¤à¥à¤®à¥à¤¬à¤à¥à¤¯ à¤à¤² पà¥à¤°à¤µà¤¾à¤¹ मà¥à¤à¤° Specification

- मौज़ूदा रेंज

- मिलियम्स (एमए)

- रेज़ोल्यूशन

- digits Flowrate, Totalizer: 10 digits Totalizer

- नमी%

- 5 To 95 % Rh

- प्रेशर रेंज

- 10 Bar

- व्यास

- मिलीमीटर (mm)

- सुरक्षा

- IP65 / IP68 on demand

- एप्लीकेशन मीडिया

- Conductive Liquids

- कनेक्टिविटी टाइप

- RS485 , GSM/GPRS

- सेंसर टाइप

- Various

- तापमान सीमा

- सेल्सियस (oC)

- फ़्रिक्वेंसी

- हर्ट्ज (एचजेड)

- माप सीमा

- Diameter from 15mm to 600mm

- फ्लो रेट

- 10-300 LPM

- उपयोग

- औद्योगिक

- मटेरियल

- एमएस/सीएस/एसएस

- साइज

- ऊंचाई

- सेंटीमीटर (cm)

- बिजली की आपूर्ति

- 90-260 VAC

- प्रॉडक्ट टाइप

- विद्युत चुम्बकीय जल प्रवाह मीटर

- वज़न

- किलोग्राम (kg)

- सटीकता

- %

- डिस्प्ले टाइप

- रंग

- काला

- रेंज

- 10 - 300 LPM

- चौड़ाई

- सेंटीमीटर (cm)

- लम्बाई

- सेंटीमीटर (cm)

विदà¥à¤¯à¥à¤¤ à¤à¥à¤®à¥à¤¬à¤à¥à¤¯ à¤à¤² पà¥à¤°à¤µà¤¾à¤¹ मà¥à¤à¤° Trade Information

- Minimum Order Quantity

- 1 टुकड़ा

- भुगतान की शर्तें

- आपूर्ति की क्षमता

- प्रति सप्ताह

- डिलीवरी का समय

- 7 दिन

- नमूना उपलब्ध

- No

- मुख्य निर्यात बाजार

- , ,

- मुख्य घरेलू बाज़ार

- प्रमाणपत्र

- Electromagnetic Flowmeter comes with Traceable to NABL Certification

About विदà¥à¤¯à¥à¤¤ à¤à¥à¤®à¥à¤¬à¤à¥à¤¯ à¤à¤² पà¥à¤°à¤µà¤¾à¤¹ मà¥à¤à¤°

Reliability Across Industrial Environments

Engineered to perform under diverse conditions, the Electromagnetic Water Flow Meter functions reliably across wide humidity (5-95% RH) and temperature ranges (up to 80C). Its robust MS/CS/SS construction ensures durability in challenging environments. The meters compatibility with multiple sensor types and industry-standard digital outputs make it a versatile solution for factories, processing plants, and water treatment facilities.

Advanced Digital Connectivity and Control

This flow meter provides comprehensive data access through RS485 and GSM/GPRS connectivity, supporting real-time monitoring and remote diagnostics. Its digital display guarantees clear readouts of flowrate (in digits) and totalizer (10 digits), enhancing operational transparency and process optimization. These connectivity features are especially valuable for industrial setups requiring centralized supervision and advanced automation.

FAQs of Electromagnetic water flow meter:

Q: How does the Electromagnetic Water Flow Meter operate in demanding industrial conditions?

A: This flow meter is constructed from MS/CS/SS to withstand harsh industrial environments, with an IP-rated build for moisture and humidity (5-95% Rh). It supports temperatures up to 80C and pressure up to 10 Bar, ensuring accurate and consistent performance in a variety of operational settings.Q: What materials are available for the Electromagnetic Water Flow Meter and which applications are they suited for?

A: The meter is available in Mild Steel (MS), Carbon Steel (CS), and Stainless Steel (SS). Selection depends on the fluids corrosiveness and application conditionsSS is ideal for corrosive or hygienic uses, while MS/CS are suitable for general industrial applications.Q: When and where can I use this flow meter in my facility?

A: This electromagnetic flow meter can be installed anywhere within an industrial process, water distribution line, or treatment system where accurate water flow measurement is essential. It supports pipe diameters between 15mm and 600mm, making it suitable for both small and large-scale systems.Q: What is the process for integrating this flow meter with existing monitoring systems?

A: Integration is streamlined through its RS485 and GSM/GPRS connectivity options, enabling seamless connection to SCADA or remote monitoring platforms. The 4-20 mA output further facilitates communication with process control systems. Physical installation is simple, thanks to its standardized dimensions and mounting compatibility.Q: How is the digital display and totalizer beneficial for industrial users?

A: The digital display delivers real-time, easy-to-read flowrate values, while the 10-digit totalizer enables long-term tracking of cumulative water use. This supports efficiency management, leak detection, and regulatory compliance reporting, thereby optimizing process performance and resource allocation.Q: What advantages does the highly accurate (1%) flow measurement provide?

A: High accuracy ensures reliable data for process optimization, billing, and compliance. It reduces discrepancies and potential operational losses, allowing users to confidently make data-driven decisions in critical industrial processes.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in जल प्रवाह मीटर Category

एंड्रेस हॉसर फ्लो मीटर

डिस्प्ले टाइप : केवल डिजिटल

मूल्य की इकाई : टुकड़ा/टुकड़ाs

उपयोग : औद्योगिक

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

प्रॉडक्ट टाइप : एंड्रेस हॉसर फ्लो मीटर

सकारात्मक विस्थापन फ्लो मीटर

डिस्प्ले टाइप : केवल डिजिटल

मूल्य की इकाई : टुकड़ा/टुकड़ाs

उपयोग : ऑटोमोटिव

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

प्रॉडक्ट टाइप : सकारात्मक विस्थापन प्रवाह मीटर

स्टीम फ्लो मीटर

डिस्प्ले टाइप : केवल डिजिटल

मूल्य की इकाई : टुकड़ा/टुकड़ाs

उपयोग : ऑटोमोटिव

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

प्रॉडक्ट टाइप : भाप प्रवाह मीटर

वाटर फ्लो मीटर

डिस्प्ले टाइप : केवल डिजिटल

मूल्य की इकाई : टुकड़ा/टुकड़े

उपयोग : औद्योगिक

माप की इकाई : टुकड़ा/टुकड़े

न्यूनतम आदेश मात्रा : 1

प्रॉडक्ट टाइप : जल प्रवाह मीटर

जांच भेजें

जांच भेजें जांच भेजें

जांच भेजें

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese